Electric driveway gates add security to vehicles left parked outside of the garage at night.

They can turn the driveway into a safe, private play area for the kids, or simply help expand a small backyard. Yes, E-Gates are expensive because they are custom fabricated to fit your location and needs. Our system is packed with modern electronics including transmitters, receivers, wireless keypads, safety eyes and now a smart phone app by NexxGate. This allows control from anywhere, scheduling, open/closed status and much more! Hancock Fence Electric gates are as easy to operate and maintain as your garage door! If a driveway gate is on your shopping list, you will see prices vary wildly on your quotes for supposedly “the same thing”. Most quality installs will start around $10K-$12K for the gate alone, then factor in any additional fence needed to close in the remainder of the yard.

We have seen prices as low as $8,500 and be warned…“You get what you pay for“.

Poor choice of materials, thin rusty steel, horrible fabrication, motors that are too small for the weight of the gate, over-stressed parts, and rookie workmanship are quite common in the bargain gate department.

Don’t be some fence builders guinea pig while they practice building E-Gates!

This type of cheap gate will bring a lifetime of disappointment and will eventually fail to the point that it will not operate anymore. We see, repair & replace them all the time. There is nothing worse than being locked in or out of your own driveway. Frustration carries a very high price. Murphy’s law says this usually occurs when it’s pouring down rain or you are on your way to something very important.

You don’t need to know much about ugly bargain driveway gates to see whats wrong in the photos below.

Here at Hancock Fence we are not ashamed to say that we will be one of the higher driveway gate quotes you receive.

We Build Quality And Dependability, Not Quantity.

We want to your gate to work every-time, all the time, anytime you push your button, even when its pouring down rain and the power is off to your neighborhood. This is important to us, and it should be important to you.

We fabricate our frames, motor mounts, roller arms, ground tracks and catch arms in house with heavy gauge, welded, Galvanized, American steel. Galvanized steel is more costly than raw steel. It wears and weathers much better than enamel painted frames. Powder coating is great, but it will fade and blister as time goes by. Galvanized steel with painted welds has proven to be the lowest maintenance system in our experience.

We have been installing American made, All-O-Matic motors for 25 years. The new SL-100 DC motor features a state of the art brush-less 24V-DC motor for maintenance free dependability. It will pull gates up to 50 feet in length and 2000 pounds. It has a back up battery system so your gate will work if your power is out. This motor also features a quick release pedal that places the transmission in neutral so the gate can be opened or closed manually with no tools or special knowledge if all systems fail.

The release pedal can be locked with a pad lock for added security if need be. This unit includes a residential 7 year warranty from All-O-Matic. Our installs meet or beat current UL 325 gate safety standards and all electrical wiring is encased in watertight flex conduit, junction boxes and proper electrical fittings. We go through a lot of extra trouble to make sure ants and insects cannot enter the electronics area of the system and cause future problems.

Our motor of choice is the All-O-Matic SL-100 DC FP

http://allomatic.net/product.php?id=14

In our constant pursuit of perfection, we have changed the design of our larger frames to a stronger unit. We now manufacture our longer frames with a “Double Tube Bottom” design when the gate is over 24 feet in length. This design is substantially more rigid than our competitors simple box frame and our old truss frame. The double bottom tube stiffens the gate and stops the gate from bending “like a bow” due to the constant torque the chain causes. We have seen many warped and rubbery gates damaged because of chain tension. The third tube also adds horizontal strength so sagging between the wheels or on the ends is never a problem.

Hancock Fence also likes nice, clean installs. If you will notice in the photos above, (click on image to enlarge) there are no weld tabs, no bolts, nuts or nails sticking out or showing. No fasteners of any kind exposed. We use double fasteners at every intersection of the wood & steel. All of of our frame fasteners are hidden and cannot be seen from either side of the gate.

Safety Is Another Key Factor

Hancock Fence uses only high quality safety eyes that stop the gate from closing if anything is in the gate path.

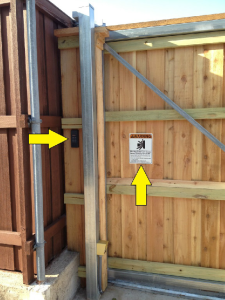

The lower yellow arrow illustrates another key factor. All of our exposed wiring is protected inside heavy duty, flexible conduit. We see many cheaper systems installed with the wires exposed and the landscapers “weed eater” has cut into the lines causing shorts in the wire rendering the gate inoperable or intermittent at best.

We also take great care to water seal all unions especially blocking out ants and spiders. They tend to get inside the units and set up camp on the warm circuit boards which starts causing intermittent problems.

The second photo above shows that we can install a wireless keypad which is code programmable. Once again, we try to install it in a shady area when possible to prolong the life of the unit and the battery. It’s made to tolerate the sun and weather, but we all know it’s going to last longer in the shade. We also take the time to install the safety sign that comes with each unit. Others don’t…..

ANOTHER THING WE DO DIFFERENT

That goes unnoticed (but really matters) is what we call a “Gate Bypass Catch”.

Most gate installers stop their gates directly against the side of the catch post, bumping directly into the post to stop. The problem with this method is that over time, the chain stretches, temperature changes, and the gate changes. This means the gate will not, and does not stop in the exact same location every time. Placement is better when new… but as time goes by, it gets worse. It’s the nature of the beast.

If it hits the post too hard, it thinks something is wrong and opens by itself. If it does not close all the way, it leaves a gap that you can see through. Sometimes the gap can be quite large! This is a great opportunity for service calls to adjust the gate and bring in extra money.

Hancock fence employs the bypass system with those mentioned natural changes in mind. As you can see, the gate passes in front of the catch post into an extended gate catcher bracket. This allows 4-6 inches of “float” so if the gate stops a little short or a little long… it doesn’t matter. It works every time with no adjustments or service calls.

Thank You For Researching This Far.

We hope you found this information educational and helpful. We have many more tips and tricks up our sleeve but cannot explain everything here. Our competition has been known to copy our work and we don’t want to give away all our secrets!

We will be happy to explain further, answer any and all questions you may have. We understand this is a serious investment in your property and we always treat it as such.

Feel free to email or call the office at (972) 747-9906

Thank you again from everyone here at:

Hancock Fence & Fabrication LLC