Knot Repair School

We are often asked

“If a knot falls out leaving a knot hole, what do I do”??

The most important thing is to pick up the knot right away and save it! Do not lose the knot.

If a lawn mower runs over it, chances are it will be lost or chopped into pieces.

Our favorite glue to date is “Titebond 3” which can be found at your local home center. Most any waterproof, outdoor glue will do just fine. We like the Titebond because it dries to a nice brown color which matches the color of the wood very well.

Get the knot and familiarize yourself with how the knot fits in the hole. It will usually only fit one way.

Once you have that figured out simply get your glue and apply it to the picket wall of the knot hole and to the outer edge of the knot itself.

Install the knot back in the hole and position for best fit. Go ahead and check the rest of the fence for loose knots and take care of them while you have your glue out.

Generally, once you glue the knot, you should not have to do it again.

Wipe off any excess or drips and let it dry! That’s it!!

Here is a video to show you how….

Did you know that the best time of the year to replace your fence is during the fall and winter?

After 32 years in the fence replacement business we have noticed annual patterns that come back year after year. People seem to be less likely to embark on home projects or fence replacement right after labor day. We always see a slower period from “back to school time” until April of the following year. There are variables from year to year, but in general… we expect it.

We always keep busy from season to season, but during the spring and summer we easily become overwhelmed and this leads to long wait times and honestly less time getting to know our customers. Our crazy spring storms don’t help at all!

During the fall and winter we are not so “pressed” so we get to spend more quality time with our customers. We see material prices stabilize, the schedule is less hectic, and generally the weather is fine. Our installers like the cold weather while they are working. You can always put on more layers to keep warm.

Nobody likes working in the rain or snow, but luckily we don’t have too much of that.

If you are not in a pinch and can wait to schedule your fence replacement until the fall, we highly recommend it. We can usually offer you slightly better prices and our service cant be beat!

Hancock Fence – Made In America!

Our annual fence improvements beginning in 2013 will include a push to use as many American made products for our fences that we can get our hands on. We believe this is important to create and support jobs here in the U.S.A. This push is a result of continuing disappointment and failure of imported products.

The cost reduction and possible damage to our reputation is not worth it…

As of January 29th 2013 we are proud to announce that we are using the following products made within our borders keeping our fellow Americans fed and busy!

These products easily equate to 98% of an entire Hancock Fence.

Steel Fence Posts

http://www.ljtube.com/

http://midwesttubemills.com/

Quick Rok

http://www.ameristarfence.com/cement-mix-quick-setting-qikrok

2×4 & 2×6 MCQ Pressure Treated

Simpson Aluminum Ring Shank Nails

Simpson Slam Brackets and Rail Anchors

http://www.strongtie.com/products/connectors/A.asp?source=strapscat

TXI Maximizer Concrete

http://www.maximizerconcrete.com/

Simpson PGT2E Pipe Grip Brackets

http://www.strongtie.com/products/connectors/PGT2E.asp?source=fencecat

Western Red Cedar

http://reichertfencing.com/

http://www.cedarcreek.com/

http://www.bc.com/wood/lumber.html

(Cedar logs are often shipped in from Canada but milled here in the states)

Hancock Fence uses the above quality components on all of our fences for maximum strength and durability. We do not buy “whatever is on sale or clearance” at our local home centers.

The only thing left is miscellaneous hardware consisting of mostly nuts and bolts.

We are working on that next!

*Our heavy gauge (sch.40) steel pipe is sometimes imported.*

We and all the people who work at the above companies appreciate your support by supporting American products and choosing Hancock Fence as your fence contractor.

The BIG Mistake

The biggest mistake we see year after year, is people who wait until their fence blows down, then they seek a replacement.

“If it ain’t broke, don’t fix it!” We can’t tell you who first coined that phrase, but We can tell you most people follow that advice. Human nature makes it easy to put things off that need to be addressed, especially when it comes to spending money.

Today’s topic is your backyard fence. For example: would you leave for a long road trip in a car that you know has problems? Do you risk being inconvenienced or stranded? It’s the same thing with your fence. Don’t risk being stranded with a broken down fence after the next wind storm.

WANTING a new fence and NEEDING a new fence are two very different things.

WANTING a new fence generally affords you time to shop around, do some research, and compare ideas about fences that would best suit you and your needs. You have time to think, time to budget, and time to put together a plan that fits in with your financial schedule.

NEEDING a new fence generally means that you, and many others like you, have waited until after the storm and now… your fence is lying in the alley and you are forced to do something immediately whether you and your bank account are ready or not. You have known for a long time that your fence was in rough shape but kept putting it off. Now you don’t have a choice.

Many homeowners assume that if they wait for their fence to be blown down by a wind storm, their insurance company will pay for a brand new fence. They are usually very, very disappointed, and find themselves stuck between a rock and a financial hard place.

Here’s What You Can Do:

Avoid the “after-the-storm contractor scramble” by planning ahead and not waiting until your fence has blown down before you consider replacement.

Fence companies that are reliable, trustworthy, and do a good job generally stay booked out for at least 2 – 4 weeks. When you need a fence… and you need it now, this waiting period can seem like an eternity, especially for pet owners.

Replace your fence on your terms, not the weather’s. Waiting to replace until after a storm usually means you will have to wait longer for an honest, dependable fence contractor. If you have a particular, well-known, contractor in mind, you may have to wait even longer because many other people in your same situation probably want to use them too.

Also, visiting with your insurance adjuster before the next storm will better prepare you for what you can expect from them. Ask very specific questions about different fence scenarios and how they will affect you in your time of need. That way you can be the judge of what risks you are willing to take with your dilapidated fence and our nasty Texas wind storms. One important thing to keep in mind… your local fence companies are not set up for immediate disaster relief. There are no 24 hour emergency fence hot lines to call. You will have to rush for position, get in line, wait, and get taken care of in a normal and orderly fashion.

You Are At Risk:

If your fence has wooden posts and is more than 5 years old. Typical “builder grade” fences are intended to last about 4 – 7 years and that’s it. They use materials and construction techniques that are intended to cut costs. Landscape timber posts are very common with these fences. You can identify them by their somewhat oval shape versus a square shaped treated pine or cedar post. No matter how well you maintain your fence, it’s life span is limited by these posts. They will eventually begin to rot at ground level and soon fail all together. A post that snaps off at the ground makes for a very difficult repair.

The first time you experience a broken post or a blown down panel, this is a warning sign that the time to replace your fence is approaching and the clock is now ticking. People who live on corner lots or next to open parks and at the end of alleys will see their fences fail sooner than their interior-lot neighbors. These open locations take a beating from full force winds, whereas the interior lots are somewhat protected from direct hits by other fences and homes.

Open locations will require a sturdier design and stronger components to withstand nature’s surprises. For our area you should consider only steel posts set a minimum of 36″ deep in concrete with a maximum 6 foot span between each post. This is necessary to insure you will have a nice, straight, and strong fence which will stand up to anything each season brings. The foundation and the framework of a fence are the most important components.

When fence shopping, don’t let price be your main concern. The actual value of a fence is determined by how well it is built and how long it will last, not necessarily how much it costs. “Price your fence by the years, not by the foot” we like to say. For example, a $4,500.00 fence that begins to lean and fall apart in two years is much more expensive in the long run than a $5,000.00 fence that performs well for 15 – 20 years. With so many poorly built fences littering our neighborhoods, it’s easy to get the impression that wood fences just don’t last. That is not true. With the right combination of quality materials and fasteners, plus a builder who actually cares and knows what he’s doing, a fence can and will go the distance.

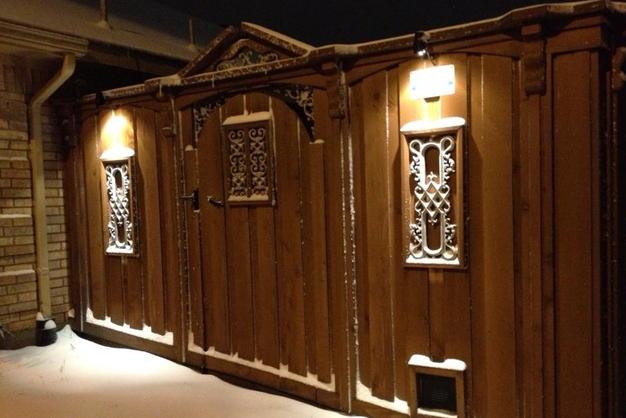

In closing, a fence is a visually important outdoor structure that is on public display. It is subject to everything mother nature can dish out 365 days a year. It is an extension of your home and can add value to your property but it can also take value away. It keeps your pets in and provides a safe and secure area for your children to play in. Fences provide privacy from unsightly surrounds so you can create a beautiful backyard environment for relaxing and personal enjoyment. Fences can be plain-Jane or dressed up to reflect an artistic flair or personal style to call your own.

With our neighborhoods placing us all closer and closer together, I believe we all have a basic responsibility to our neighbors and neighborhoods to keep our property well maintained, promoting respect and friendship between neighbors. Attractive homes with well maintained landscapes and well built fences help keep neighborhoods looking nice and property values high. After all, everyone wants to live in a “nice neighborhood”, right? This doesn’t just happen automatically, folks. It requires a never ending effort from all of us to make sure that Allen, Texas continues to be a nice place to live.

The Point Of Failure

Each time we replace a fence we evaluate what we see and ask ourselves

“What is the point of failure on this fence?”

Why does this fence need to replaced after only 6-7 years?

This very simple question can easily be answered by observation and common sense. To paint this scenario with a very broad brush, in general we mostly see poor choice of material, and poor assembly of those materials.

Lets break down a typical fence by its top 3 failure points and look at them individually to understand why they fail.

We will start at the ground and work our way up!

#1 Posts:

There are 4 types of posts commonly used in our area.

Treated Landscape Timbers:

Commonly found on builder grade fences. These are as cheap as it gets. Common problems are warping, splitting and rotting at ground level, which causes them to snap. These posts are dipped in preservative and not pressure treated. Dipping only preserves the outside of the post. These posts rot from the inside out, to the point of failure.

4×4 Pressure Treated Posts:

These are one step up from landscape timbers. These are pressure treated so the preservative is forced through the entire post. Rotting and snapping usually is not a problem. However treated posts are almost guaranteed to warp, split and twist causing distortion of the fence. Exactly how much is anybody’s guess. As the fence distorts, the fasteners are pulled, they loose their grip and pieces and panels begin to fall off.

4×4 Cedar Posts

Cedar posts are one step sideways from treated posts. Cedar posts are the best choice in the wood category but they are soft. Weed Eaters (string trimmers) will easily damage these posts to the point of failure. Warping is rare. Splitting is common, but usually does not effect performance. Typically these will last about 10-12 years before they rot and snap. Cedar posts limit the life of the fence dramatically. When the posts fail, they take the whole fence with it no matter how well the fence was built or cared for.

Steel Posts:

Steel posts are the best choice for fence as long as they are used properly! The photo above is a great example of steel posts gone wrong.

Many posts sold at the big box stores are thin wall steel to be used with chain link fence only. Chain link has minimal wind load whereas a solid fence must be built differently. The average consumer will select the cheaper post not knowing all steel posts are not equal.

Here at Hancock Fence:

We only use 13 gauge pipe, spaced no more than 6′ apart and a minimum of 36″ deep, set in concrete for great wind load strength. We also offer a “schedule 40” pipe that is almost twice as thick as our 13 gauge. 40’s are expensive, but are really stout. Our 13 gauge posts serve most situations quite well.

We stopped installing wood posts in 2003 for all the above reasons.

Wood posts are almost always the point of failure.

#2 Horizontal Rails

The “Rails” are the skeleton of the fence. Their job is to tie everything together. If the skeleton is weak or over spanned, it will sag and begin to fall apart from simple stress, gravity and soil movement.

8′ post spacing is very common. This is too far apart to suspend an average fence panel. Saggy panels and failure are on the menu as soon as its built. Many builders will simply set the fence on the ground to stop sagging. Now they have created a situation where the bottom of the fence will rot and possibly attract termites.

Rails are the second biggest point of failure we see.

Please visit our “Treated vs. Cedar Rails” page for photos and information on rail do’s and dont’s.

#3 Construction Technique

Fences that are assembled incorrectly will not stay together. Brackets, nails and screws cant do their job if they are not used correctly.

In order to build a long lasting fence, these materials and methods must be avoided. When your new fence is built, imagine a timer being set. No fence will last forever, so the clock is ticking. Time on the clock is limited or substantially reduced if one of these items are installed on your fence.

Hancock Fence focuses on using only components that will maximize the time on your clock. We want our fences to stay together & look better longer than our competitors. We believe this is where the value factor really kicks in and keeps thousands of our past customers smiling at their Hancock Fence for many, many years to come.

Please feel free to contact us with any questions. We are always happy to help!